Air circuit breakers are electrical devices that help prevent damage and potential hazards by breaking the circuit flow when electrical faults are detected.

These devices stand as essential guardians within industrial power systems.

When excessive currents like short circuits or overloads threaten, these specialized devices leap into action – interrupting electricity flow to prevent potentially catastrophic damage.

In factories, plants, and large commercial facilities alike, an electrical fault could spell disaster. ACBs are the frontline defense, maintaining the integrity of the entire system.

This guide unveils the inner workings of air circuit breakers – their principles, types, applications, selection criteria, installation, and so much more.

Read on to learn more.

Simplicity underpins an ACB‘s operation. But in order for you to understand how air circuit breakers work, you have to know the construction first.

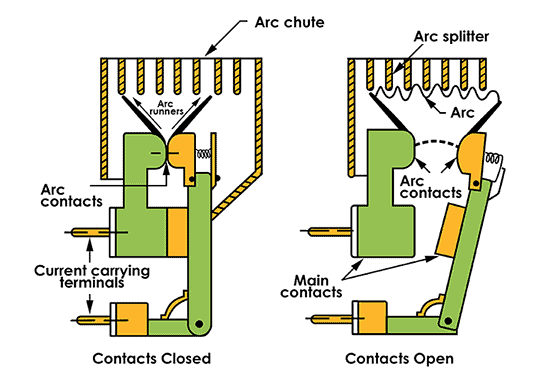

An air circuit breaker (ACB) is made up of several key parts designed to control, contain, and extinguish electrical arcs to protect circuits. Here’s a brief description and function of each part:

| Arc Chute | A chamber with metal plates arranged to capture and cool the arc when it forms. Its main function is to split the arc into smaller segments, dissipating heat quickly and extinguishing the arc, which helps protect the circuit from damage. |

| Arc Spitter | Metal plates within the arc chute divide the arc into smaller segments. This splitting reduces the arc’s intensity, making it easier to extinguish, thus protecting the breaker from overheating and extending its lifespan. |

| Arc Runners | Conductive strips that guide the arc from the main contacts to the arc chute. Their function is to direct the arc away from sensitive areas and into the arc chute where it can be safely managed and extinguished. |

| Arc Contacts | Specially designed contacts that handle the arc when the breaker operates. They bear the brunt of the arc energy, protecting the main contacts from wear. By absorbing arc damage, they ensure the main contacts last longer, enhancing the breaker’s durability. |

Air circuit breakers rely on two sets of contacts: main contacts, made of silver-coated copper to minimize contact resistance, and arcing contacts, crafted from a heat-resistant copper alloy.

As the breaker’s contacts separate, an arc forms between them.

However, this arc is quickly extinguished by a surge of compressed air.

This air cools and elongates the arc until it ceases, interrupting the current flow.

During operation, the main contacts close first to carry the current and separate first to transfer the arc to the arcing contacts, reducing wear on the main contacts.

Consistent, reliable operation hinges on this compressed air supply, provided by an ever-ready compressor or reservoir.

Steel inserts in the arc chute generate a magnetic field that pushes the arc upward, where it is split and cooled by steel plates in the chute.

The arc is ultimately quenched as it lengthens, cools, and loses power, although, at lower currents, quenching may be less efficient due to weaker electromagnetic forces.

While creating and extinguishing an arc in the air remains the core concept, ACBs take various forms tailored to unique operating conditions.

Simplicity is the hallmark of this design. The contacts separate in a chamber filled with compressed air, and the air blast is directed across the arc path. This cross-flow of air causes the arc to elongate and eventually extinguish. These breakers are often used in lower-voltage applications.

These breakers employ a strong magnetic field in addition to the air blast. The magnetic field causes the arc to rotate and elongate, enhancing the arc’s cooling and extinguishing process. This design is particularly well-suited for high-voltage applications where the arc is more intense.

For high-voltage transmission and distribution systems, the air blast circuit breaker is ideal. It employs a powerful blast of compressed air—generated by a high-pressure reservoir or compressor system—to rapidly elongate and extinguish the arc. These breakers are engineered to handle the immense energy levels encountered in such applications.

Imagine a series of insulating plates or chutes guiding the arc as it forms. The arc is forced to travel through these chutes, where it encounters the cooling and extinguishing effects of the air blast. This design finds widespread use in medium-voltage applications.

Air circuit breakers are nothing if not versatile. They are a favored choice in numerous industrial applications, including:

In high-voltage transmission and distribution systems, air blast circuit breakers take center stage. These gadgets withstand and extinguish arcs fueled by immense electrical energies, safeguarding intricate networks that route power across vast distances.

A sustained arc in such systems could trigger widespread outages and wreak havoc. Enter the air blast ACB – unleashing torrents of compressed air to forcibly elongate and quell even the most formidable arcs, averting catastrophe.

Industrial plants and commercial buildings operate within the medium-voltage arena, their electrical arteries carrying substantial yet measured currents. Here, air chute and magnetic blowout ACBs shine, offering versatile arc management solutions.

Air chute breakers employ insulating chutes to funnel and chill the arc, while magnetic blowout models wield electromagnetic forces to catalyze arc rotation and elongation before the air blast extinguishes it.

An ACB’s short-circuit current rating measures its ability to withstand and interrupt extreme fault currents that surge through during short circuits. This rating reflects the breaker’s electromechanical endurance, ensuring it can safely contain and extinguish the arc without sustaining damage. Higher ratings equate to enhanced short-circuit resilience, a vital consideration for applications prone to such events.

While short-circuit events demand momentary heroics, ACBs must also exhibit unwavering performance during steady-state operations. Their continuous current ratings define the maximum load they can reliably conduct without overheating or compromising insulation integrity. This metric guides selection for applications with known, sustained current demands, ensuring the chosen ACB operates well within its thermal limitations.

Choosing the ideal air circuit breaker isn’t a one-size-fits-all endeavor. Several key factors dictate the optimal solution.

Perhaps the most fundamental consideration – the application’s voltage and current parameters must seamlessly align with the ACB’s ratings.

Selecting a breaker inadequately rated could prove disastrous, unable to contain or interrupt faults effectively. Conversely, over-specifying leads to unnecessary costs. Prudent matching of ratings to operational conditions is paramount.

ACBs don’t operate in controlled, sterile environments. Temperature extremes, humidity levels, indoor/outdoor conditions, and potential pollutants or contaminants all impact performance and longevity.

An indoor, climate-controlled industrial facility allows different ACB options compared to an outdoor substation subject to the elements. Environmental appraisals guide suitable selections.

Spatial constraints frequently arise, necessitating compact ACB designs that optimize footprint without compromising functionality. Input/output cable routing, maintenance access requirements, and clearances around the breaker all factor into the dimensional equation. For confined spaces, models with ingenious space-saving geometry prove invaluable.

Like any hardworking component, ACBs require periodic maintenance to ensure lasting, reliable service. Some designs facilitate easier accessibility, faster inspections, and smoother part replacements compared to others. Where maintenance demands are stringent or operational downtimes costly, models prioritizing maintainability take precedence.

When it comes to ACBs, proper installation and consistent maintenance are pivotal. Here are a few general guidelines:

Site preparation is crucial before an ACB starts its duties. This includes assessing the clearance to accommodate operation, maintenance access, and ventilation. Structural evaluations ensure the mounting surface can withstand the breaker’s weight and electromagnetic forces during hazards.

Rigorous installation guidelines dictate critical aspects like cable terminations, grounding procedures, and aligning interfaces to mitigate electrical stresses. Following these is vital for safety and performance.

Like finely-tuned instruments, ACBs require regular inspections and testing to validate operational integrity. Visual examinations identify signs of wear, overheating, or contamination that could impede functionality. Resistance measurements across contact surfaces detect degradation that could impair current-carrying capabilities.

Timing tests evaluate the breaker’s responsiveness, ensuring faults are interrupted within specified timeframes. These periodic assessments preempt potential failures and inform proactive maintenance interventions.

Even with precautions, problems may arise during an ACB’s lifespan. Overheating from heavy loads or poor ventilation remains a risk, requiring load adjustment or airflow fixes. Contact erosion from use or contaminants mandates refinishing or replacement.

Mechanical issues or faulty interlocks can hinder contact separation, needing recalibration or part replacements. Troubleshooting pinpoints issues for specific fixes.

Enforcing stringent safety protocols is non-negotiable when working with ACBs. Lockout/tagout procedures ensure equipment is properly de-energized and isolated before maintenance. Grounding practices temporarily bond conductive components to dissipate residual charges.

Personal protective equipment like insulated tools, arc-rated clothing, and face shields shield personnel from potential arc flash hazards. Emergency response plans delineate critical actions in case of incidents, mitigating risks to personnel and assets. Complacency in the presence of such formidable forces is unacceptable.

An air circuit breaker (ACB) uses air to extinguish arcs, while an oil circuit breaker relies on oil.

In an ACB, air cools and lengthens the arc, while in an oil breaker, the arc vaporizes the oil to form a gas that cools and isolates it.

ACBs are generally better for higher-current and medium-voltage applications due to their durability and arc-handling capability.

MCCBs (Molded Case Circuit Breakers) are more compact, used for low-voltage circuits, and provide reliable protection for lower currents.

The choice depends on application and voltage requirements.

Air circuit breakers are used for their ability to handle high currents in industrial applications.

They quickly extinguish arcs, provide adjustable trip settings, and are easy to maintain, which makes them ideal for protecting medium-voltage systems and ensuring reliable power distribution.

Air circuit breakers are commonly used in industrial facilities, commercial buildings, and data centers.

They protect medium-voltage electrical systems from overloads and faults, ensuring safe power distribution in applications that require high current and robust protection.

A circuit breaker is a device that interrupts electrical flow during faults. An air circuit breaker is a specific type that uses air to extinguish arcs, mainly used in medium-voltage systems.

Other breakers may use materials like oil, gas, or vacuum for arc suppression.

An ACB can trip due to overloads, short circuits, ground faults, or mechanical issues. It detects abnormal current flow or faults and triggers to protect the circuit.

Environmental factors like dust or moisture can also impact its sensitivity, causing unexpected trips.

Ensuring air circuit breakers conform to established industry standards and certifications is paramount for guaranteeing performance, safety, and interoperability across diverse applications. When it comes to ACBs for industrial applications, there are numerous industry standards and certifications to ensure quality:

These comprehensive standards encompass design, construction, testing methodologies, ratings, and performance criteria for ACBs across voltage classes. Adherence to these guidelines is important as it instills confidence in specifiers, installers, and end-users alike.

Air circuit breakers are vital for safeguarding industrial power systems against excessive currents and electrical faults. But their vital role extends far beyond just playing defense against potential chaos.

Through ingenious designs tailored for diverse applications and stringent adherence to industry standards, ACBs cultivate an environment of unwavering safety, reliability, and operational excellence. They’re not just fail-safes – they’re enabling factors that allow industrial electrical systems to operate at peak performance.

From the meticulous site prep and installation to the ongoing maintenance and strategic troubleshooting, diligent practices unlock ACBs’ full potential as arc-extinguishing dynamos. And as industrial power demands continue escalating, you can bet these breakers will remain indispensable guardians, fortified by technological innovations and an unwavering commitment to quality.

When it comes to protecting your critical power arteries, turn to the air circuit breaker experts at iALLway. As a global leader in electrical safety solutions, we offer a comprehensive range of ACBs alongside unparalleled support services. Contact iALLway today and safeguard your operations with the industry’s finest.

I don't think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://accounts.binance.com/pt-BR/register-person?ref=YY80CKRN

I don't think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don't think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your article helped me a lot, is there any more related content? Thanks!

Your article helped me a lot, is there any more related content? Thanks!

I don't think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don't think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Muchas gracias. ?Como puedo iniciar sesion?

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Hello! I could have sworn I've been to this website before buut after looking at some of the posts I realized it's new to me. Anyways, I'm definitely happy I discovered it annd I'll be bookmarking it and checking back often! https://Zeleniymis.com.ua/

That is very interesting, You are a very professional blogger. I've joined your rss feed and look ahead to in searchh of extra of your exccellent post. Additionally, I've shared yor web site in my social networks https://Odessaforum.BIZ.Ua/

Your article helped me a lot, is there any more related content? Thanks!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.