In order to serve our clientele well, we have an easy step-by-step service system and process that can help our clientele save a lot of time, establishing a long-term and stable professional partnership.

·Engage in extensive consultations with the client to comprehend their specific needs and requirements.

·Discuss the client's electrical protection requirements, including the application areas (e.g., industrial, residential, agricultural, renewable energy, etc.).

·Determine the client's technical specifications and performance requirements, including required current ratings, breaking capacity, and more.

·Negotiate specific customization requirements with the client to meet their unique demands.

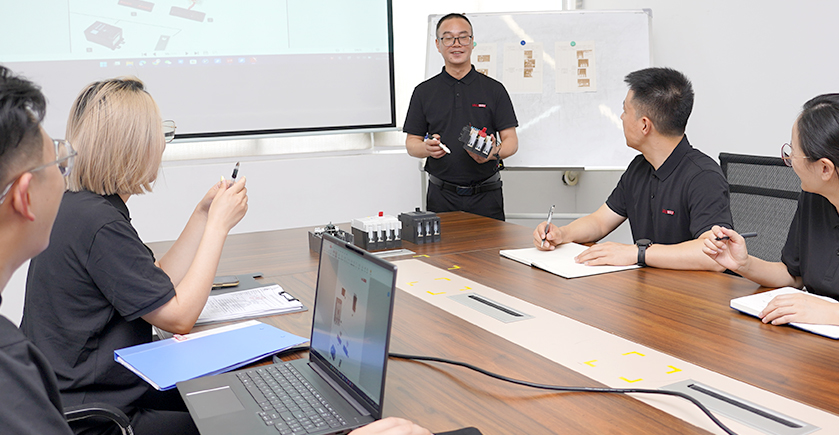

·Provide clients with expert technical support, including technical specifications and performance features of Molded Case Circuit Breaker (MCCB) products.

·Arrange meetings to discuss technical details, progress, and plans.

·Ensure that clients have a clear understanding of the technical intricacies of the solution to meet their needs.

·Select appropriate materials and construct MCCBs based on the client's requirements.

·Provide samples for client evaluation and approval.

·Make necessary modifications and improvements based on client feedback.

·Commence large-scale production of MCCB products.

·Ensure that the production process adheres to quality control standards and timelines.

·Maintain communication with the client, providing timely updates on production progress.

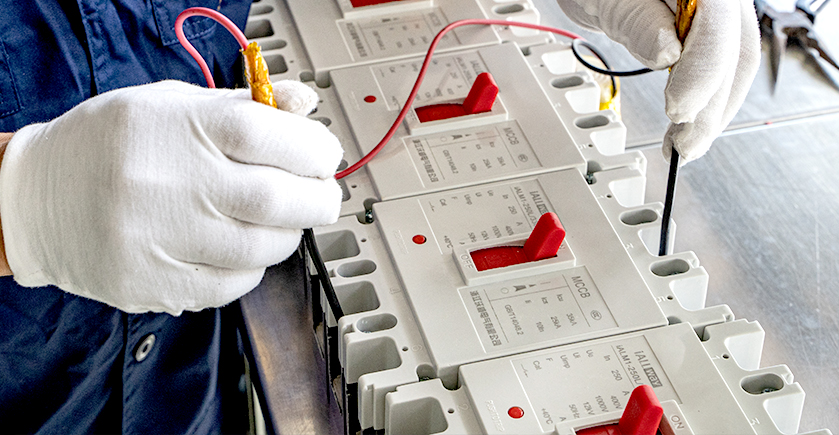

·Conduct rigorous quality checks and testing during the production process to ensure that each MCCB complies with quality standards.

·Verify product performance and safety, including current load testing, breaking capacity testing, and more.

·Take immediate corrective actions if any quality issues are identified.

·Properly package MCCB products to ensure they are free from damage while in transit.

·Arrange for product delivery, ensuring products are delivered to the specified locations as per the client's requirements.

·Provide comprehensive delivery documentation and information.

·Continue to offer technical support and service after delivery to ensure client satisfaction with the products.

·Address any post-sales issues and maintenance requirements.

·Establish long-term cooperative relationships with clients to meet their future electrical protection needs.

Our partnership with Wuhan University brings new perspectives and valuable resources, empowering our R&D and enhancing our products, exceeding customer expectations, and creating greater value.

In the realm of smart homes and buildings, our MCCBs and integrated electrical systems employ cutting-edge sensors, intelligent switches, and automation controls. With this technology, our electrical systems enable intelligent control over household devices, lighting, and security systems, embracing the convenience and efficiency of a seamlessly interconnected smart environment.

With the aid of our MCCB (Molded Case Circuit Breakers), users gain the capability to remotely monitor and manage renewable energy systems, promptly address faults, and conduct essential maintenance, thereby reducing downtime and enhancing system reliability. This array of innovations positions our MCCB products as the pivotal element in shaping the future of renewable energy, paving the way for the sustainable development of clean energy sources.

Seamless integration into charging stations and equipment ensures reliable electrical protection while continuously monitoring and reporting on the charging status. Moreover, MCCBs enable remote control and data analysis, granting users real-time access to charging status and energy consumption data. This data-driven approach optimizes charging strategies and energy management.